Top Oil Seals Manufacturers & Suppliers: How to Choose the Right One

Oil Seals and Their Importance in Industrial Applications

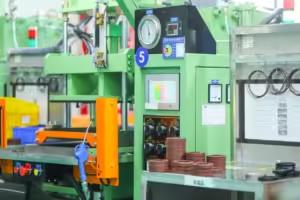

Oil seals play a vital role in many industries, serving to prevent leaks and ensuring that machinery and vehicles run smoothly. These small but critical components are designed to maintain lubricants and other fluids within sealed systems, preventing contamination and damage. Whether in automotive engines, manufacturing equipment, or aerospace applications, oil seals are indispensable for maintaining operational efficiency.

Manufacturers and suppliers of oil seals are integral to providing high-quality solutions that meet industry standards. Their expertise ensures optimal performance, reliability, and longevity of the components, which in turn boosts productivity and reduces maintenance costs. In this article, we will guide you through the process of choosing the right oil seal manufacturer and supplier to meet your needs.

Global Market Demand for Oil Seals

The oil seal market is growing rapidly, driven by an increasing demand for high-performance sealing solutions across various sectors. According to market research, the global oil seal market is expected to reach XX billion USD by 2028, with a compound annual growth rate (CAGR) of X%. This expansion is attributed to the rise in demand for reliable seals in automotive, aerospace, manufacturing, and energy industries.

As industries continue to expand, the need for durable and effective sealing solutions is more crucial than ever. Understanding this growing demand will help you select a supplier that is poised to support your business in the long term.

Industry Pain Points

Many industries face significant challenges when it comes to maintaining operational efficiency. Common issues like oil leaks can lead to costly downtime, which not only disrupts production but also leads to increased maintenance costs. These problems can cause major financial strain, making it essential to choose a reliable oil seals supplier that can ensure quality and prevent costly failures.

For distributors, maintaining a steady supply of high-quality oil seals is critical. A dependable supplier can offer a competitive advantage, leading to customer satisfaction and long-term business success. Selecting the right partner is paramount to navigating these pain points successfully.

Purpose of This Article

This article aims to provide a comprehensive guide on how to select the right oil seals manufacturer and supplier. By focusing on key factors such as quality assurance, manufacturing capabilities, and reputation, you will be able to make an informed decision that ensures both the performance and longevity of your equipment.

What Are Oil Seals?

Oil seals are essential components used to prevent the leakage of oils, lubricants, and other fluids in mechanical systems. Their primary function is to seal off the gap between rotating and stationary parts of machinery, effectively keeping fluids contained and contaminants out.

H3: Types of Oil Seals

- Rubber Oil Seals: The most common type, offering flexibility, resilience, and resistance to various chemicals.

- PTFE Oil Seals: Known for their excellent chemical resistance and ability to operate under extreme temperatures.

- Metal Oil Seals: Often used in heavy-duty applications where high performance is required, such as in industrial machinery.

Oil seals are widely used across industries like automotive, aerospace, and manufacturing. Each type is designed to cater to specific operational conditions, ensuring performance in the most demanding environments.

Key Factors to Consider When Choosing an Oil Seals Manufacturer

Quality Assurance and Certification

When choosing an oil seal manufacturer, quality assurance is paramount. Look for certifications such as ISO 9001 or IATF 16949, which demonstrate that the manufacturer adheres to strict quality control processes. Reliable manufacturers will have robust testing protocols in place to ensure the seals meet performance standards and can handle extreme conditions.

Manufacturing Capabilities

A reputable manufacturer should offer a wide range of materials and customization options. Whether you need standard seals or tailored solutions, their manufacturing capabilities should align with your specific requirements. Additionally, consider their production capacity and lead times to ensure they can meet your delivery demands.

Experience and Reputation

The manufacturer’s experience in the industry speaks volumes about their reliability. Established companies with years of expertise and positive customer reviews are typically safer choices. Look for case studies or testimonials to gauge the company’s track record.

Technological Advancements

Innovative manufacturers invest in modern production techniques, such as CNC machining and advanced molding methods. Their research and development (R&D) capabilities are crucial in creating cutting-edge sealing solutions that meet evolving industry needs.

Cost and Value Consideration

Balancing quality and cost is essential when evaluating potential suppliers. While the lowest price may seem attractive, it often compromises quality. Ensure you are getting the best value by considering the long-term performance and durability of the seals, which can save you more in maintenance and repairs over time.

Market Trends and Future Developments

The oil seal industry is undergoing significant transformation, with trends such as the adoption of eco-friendly materials and the integration of automation into manufacturing processes. These developments are helping companies reduce environmental impact and improve production efficiency.

By selecting a forward-thinking supplier, you can ensure your business stays ahead of the curve and meets future demands.

Top Oil Seals Manufacturers Worldwide

Here are some of the leading manufacturers recognized for their excellence in producing high-quality oil seals:

SKF (Sweden)

Headquarters: Gothenburg, Sweden

Advantages: Known for their high-quality seals, SKF offers a wide range of sealing solutions for various industries, including automotive, industrial machinery, and aerospace.

Website: https://www.skf.com

Freudenberg Sealing Technologies (Germany)

Headquarters: Weinheim, Germany

Advantages: Specializing in customizable sealing solutions, Freudenberg is a leader in material science and serves industries like automotive, oil & gas, and medical.

Website: https://www.freudenberg-sealing.com

Trelleborg Sealing Solutions (Sweden)

Headquarters: Trelleborg, Sweden

Advantages: Trelleborg focuses on premium elastomeric seals and sustainable sealing solutions for aerospace, automotive, and industrial sectors.

Website: https://www.trelleborg.com/en/sealing-solutions

Parker Hannifin (USA)

Headquarters: Cleveland, Ohio, USA

Advantages: Offering a broad range of sealing solutions, Parker Hannifin serves aerospace, automotive, and fluid systems industries.

Website: https://www.parker.com

NOK Corporation (Japan)

Headquarters: Tokyo, Japan

Advantages: Known for their rubber sealing solutions, particularly in the automotive industry.

Website: https://www.nokcorporation.com

DRO, we are working hard to learn from these industry leaders and improve our manufacturing processes and service offerings to meet global standards.

At DRO, we offer flexible customization options to meet the unique needs of our clients. For orders exceeding $2,000, we provide complimentary laser engraving of your company logo on the oil seals, adding a personalized touch to your products. Additionally, for orders over $10,000, we offer free customization of your outer packaging. This allows our clients to enhance their product branding, improving marketability and fostering stronger brand recognition.

How to Evaluate Potential Oil Seals Manufacturers & Suppliers

Requesting Samples for Testing

Testing sample products is a crucial step to evaluate their performance, durability, and compatibility with your systems. Ensure the manufacturer provides samples to assess the quality before committing to large orders.

Supply Chain Transparency

A good supplier should offer transparency about their sourcing and production processes. Ensure they follow ethical and sustainable practices, which are becoming increasingly important in today’s market.

After-Sales Service and Warranty

Check the warranty terms and after-sales service offered by the manufacturer. A strong after-sales service can save you time and money if issues arise with the seals.

Customization and Flexibility

Choose a manufacturer that offers customization options tailored to your specific industrial needs. Flexibility in design and materials can make a significant difference in achieving the best performance in your systems.

Benefits of Choosing the Right Oil Seals Manufacturer & Supplier

By selecting the right supplier, you can enhance the performance and longevity of your equipment. This will lead to reduced downtime, fewer maintenance costs, and overall increased productivity, benefiting your business in the long run.

Conclusion

In conclusion, choosing the right oil seals manufacturer and supplier is critical to ensuring the efficiency and reliability of your machinery. Consider factors such as quality, experience, technological advancements, and cost when making your decision.

If you are ready to explore the best oil seal solutions for your business, contact us today for a consultation.