A Comprehensive Guide to NBR TC Oil Seals: Design, Applications & Benefits

1. What are NBR TC Oil Seals?

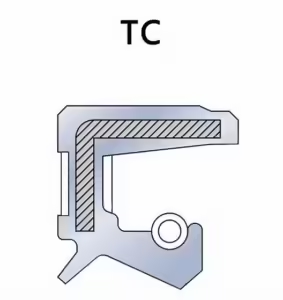

NBR TC oil seals are vital components designed to effectively seal rotating shafts, preventing fluid leaks and contamination. “TC” refers specifically to a double-lip seal featuring a primary sealing lip, secondary dust lip, garter spring for radial load consistency, and an outer rubber coating for enhanced sealing and easy installation. Nitrile Rubber (NBR) dominates TC oil seal designs due to its cost-efficiency, reliability, and adaptability in various industrial applications.

2. Key Material Properties of NBR (Nitrile Rubber)

Chemical Composition & Structure

NBR is a synthetic elastomer renowned for its acrylonitrile-butadiene composition, providing superior resistance to petroleum-based oils, fuels, water, and numerous chemicals.

Performance Characteristics

- Temperature tolerance typically ranging from -40°C to 120°C.

- Robust mechanical properties: high tensile strength, optimal hardness, and low compression set.

- Exceptional wear and abrasion resistance.

NBR vs. Other Elastomers (FKM, EPDM, Silicone)

NBR excels in cost-performance balance, outperforming other elastomers like FKM, EPDM, or Silicone in environments dominated by oils and moderate temperatures.

3. Structural Advantages of NBR TC Oil Seals

Double-Lip Design

- Primary lip ensures effective fluid sealing.

- Secondary dust lip significantly prolongs equipment life by preventing external contaminants.

Integrated Metal Insert

Provides structural integrity and enhances overall seal stability.

Outer Rubber Coating

Offers superior sealing against housing bores, easing the installation process.

Role of Garter Spring

Maintains consistent radial force on the shaft, optimizing sealing performance during operation.

4. Performance Benefits of Using NBR TC Oil Seals

- Reliable sealing performance in both static and dynamic operations under moderate loads.

- High resistance against wear, tear, and deformation.

- Ideal for lubricated applications involving mineral oils and greases.

- Excellent balance of performance and cost compared to more expensive materials like FKM.

5. Applications Where NBR TC Oil Seals Excel

Automotive Industry

Widely used in crankshafts, gearboxes, axles, and heavy-duty transmission systems.

Industrial Equipment

Critical for hydraulic pumps, compressors, and electric motor applications.

Agricultural & Construction Machinery

Ideal sealing solution for tractors, excavators, and other heavy-duty equipment.

Consumer Appliances

Commonly employed in household devices requiring reliable shaft sealing.

6. Installation & Maintenance Best Practices

Installation Guidelines

- Ensure optimal surface finish for shafts and housing bores.

- Maintain proper alignment and apply lubricant to prevent seal damage.

- Avoid common mistakes such as excessive force during seal pressing.

Storage & Handling Tips

- Store seals away from direct sunlight and heat to maintain integrity.

- Handle seals with care to prevent pre-installation damage.

7. Understanding Limitations & When to Consider Alternatives

- NBR is not suited for high-temperature (>120°C) or aggressive chemical environments.

- Limited UV and ozone resistance compared to alternatives like FKM or Silicone.

- Consider upgrading to FKM or HNBR for enhanced thermal or chemical resistance.

- Evaluate application specifics to determine NBR suitability.

8. Customization Opportunities for NBR TC Oil Seals

- Dimension adjustments, lip design variations, and spring material options (e.g., stainless steel).

- Specialized surface treatments and coatings available for unique applications.

- Color coding for quick identification and inventory management.

9. Why Choose D&R Industry for NBR TC Oil Seals?

- Tailored in-house formulation and custom compound development.

- Precision tooling and tight dimensional control for consistent product quality.

- ISO-certified quality assurance and extensive global distribution experience.

- Proven track record serving automotive Tier 1 suppliers and top industrial companies.

- Competitive pricing paired with efficient production lead times.

10. Contact D&R for Quotations and Engineering Support

- Request product samples, quotes, or submit custom specifications directly online.

- Dedicated engineering assistance available for specialized requirements.

Contact Information:

- Website: drorubber.com

- WhatsApp: +0086 15815831911

- WeChat: +0086 13784044874