SC vs. TC Oil Seals: How to Select the Right Seal for Your Machinery

Introduction: The Importance of Choosing Between SC and TC Oil Seals

Choosing the correct oil seal is crucial for protecting rotating shafts, preventing contamination, and maintaining lubrication efficiency. Improper selection of oil seals causes over 20% of mechanical failures annually. Understanding the differences between SC and TC oil seals will help international buyers and engineers enhance machinery lifespan, reduce downtime, and lower maintenance costs. This guide explores the critical distinctions between these popular oil seal types.

SC vs. TC Oil Seals: Definition and Structural Differences

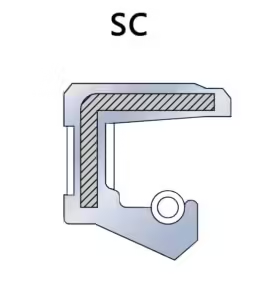

SC Oil Seals (Single Lip)

SC oil seals feature a single spring-loaded sealing lip, offering basic yet effective sealing performance. Without a secondary dust lip, they provide a simpler, more compact design, ideal for environments free of contamination.

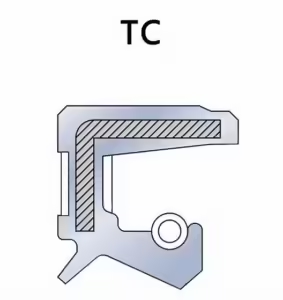

TC Oil Seals (Double Lip)

TC oil seals include a primary spring-loaded sealing lip and an additional dust lip that prevents contaminants from reaching the main sealing area. The dual-lip structure significantly enhances seal protection in harsh environments.

Visual Aid: Include a labeled diagram comparing the structure of SC and TC oil seals to illustrate clearly their differences.

Both seal types comply with global standards DIN 3760 (Type B for SC, Type C for TC) and ISO 6194-1.

Advantages of TC Oil Seals: The Dust Lip Benefit

The extra dust lip in TC seals acts as a barrier against external contaminants like dirt, mud, water, and debris. Although it increases friction slightly, it provides superior protection, reducing wear on the primary sealing lip and extending the seal’s life significantly in challenging conditions.

Applications: When to Choose SC or TC Oil Seals

SC Oil Seals: Ideal for Clean Environments

- Perfect for applications like electric motors, indoor gearboxes, precision CNC machines, and sealed systems.

- Example: Widely utilized in industrial robotics and precision machinery where contamination risk is minimal.

- Keywords: SC oil seals for electric motors, single-lip seals for clean environments.

TC Oil Seals: Superior for Harsh Conditions

- Optimal for use in agricultural machinery, automotive engines, mining equipment, aerospace landing gears, and marine propulsion systems.

- Case Study: A mining firm reported a 30% reduction in wheel-end gearbox leaks after switching to TC oil seals.

- Keywords: TC oil seals for rugged conditions, double-lip seals for outdoor machinery.

Performance Comparison: Friction, Heat Generation, and Speed

- Friction: TC seals have 5-10% higher friction due to the dust lip.

- Heat Generation: Slightly higher in TC seals, though mitigated by modern materials (e.g., NBR, FKM).

- Speed: SC seals are preferable for high-speed applications (>15 m/s), while TC seals excel in lower-speed, contamination-prone environments.

- Keywords: Low friction oil seals, high-speed shaft seals.

Material Options: Selecting the Right Seal Material

Both SC and TC seals come in various materials tailored for specific conditions:

- NBR: Cost-effective for moderate temperatures (-40°C to 100°C).

- FKM: Suitable for high temperatures (up to 200°C) and chemical resistance.

- HNBR: Best for heavy-duty, low-speed applications needing extra durability.

- Silicone: Ideal for extreme cold temperatures or food-grade applications.

- Keywords: FKM oil seal compatibility, HNBR heavy-duty seals.

Compliance with Global Standards: DIN 3760 and ISO 6194-1

- DIN 3760: Widely recognized in Europe, defining SC as Type B and TC as Type C radial shaft seals.

- ISO 6194-1: Internationally recognized standard ensuring consistent dimensions and performance globally.

- North America favors TC seals for outdoor applications, while European markets emphasize precision engineering with DIN-compliant seals.

Quick Reference Table: SC vs. TC Oil Seals

| Feature | SC Oil Seal | TC Oil Seal |

|---|---|---|

| Lip Structure | Single lip | Double lip (with dust lip) |

| Dust Protection | No | Yes |

| Friction Level | Lower (~5-10% less) | Slightly higher |

| Ideal Environment | Clean, sealed | Dusty, wet, outdoor |

| Service Life | Standard | Extended in harsh conditions |

| Standards | DIN 3760, ISO 6194-1 | DIN 3760, ISO 6194-1 |

Conclusion: Making the Right Choice for Optimal Machinery Performance

Choosing between SC and TC oil seals depends primarily on the operational environment. For clean and high-speed conditions, SC seals offer superior performance. Conversely, TC seals provide essential protection in contaminated and challenging environments. Proper selection ensures machinery reliability, efficiency, and global standard compliance.

Need Expert Advice on Oil Seals?

Contact our specialized team at DRO Rubber Seals for tailored solutions, professional material selection guidance, and OEM-quality oil seals.

- Website: drorubber.com

- WhatsApp: +0086 15815831911

- WeChat: +0086 13784044874