TC Oil Seals vs. TG Oil Seals: A Comprehensive Guide to Their Differences, Applications, and Selection

1. Introduction to TC and TG Oil Seals

Oil seals play a critical role in preventing the leakage of oils, lubricants, and fluids in mechanical systems, ensuring optimal performance and longevity. TC and TG oil seals are among the most commonly used types in various industries. Although these seals share many similarities in structure and function, understanding their subtle differences is crucial for selecting the right oil seal for specific applications. This guide compares TC vs. TG oil seals, highlighting their features, differences, and common uses.

2. What Does TC Mean on an Oil Seal?

Definition of TC Oil Seals

The term “TC” refers to a specific classification of oil seals under international standards. In Germany, TC seals are often referred to as “FB” seals. This classification helps standardize the types of seals used across various industries and geographical locations, ensuring consistency and reliability in sealing applications.

Alternative Terminology for TC Oil Seals

TC oil seals may have different names depending on the manufacturer or regional standards. For instance, in Germany, TC seals are known as FB seals. This flexibility in terminology ensures that the classification system is adaptable across global markets, simplifying communication and procurement processes.

Purpose of TC Classification

The TC classification, along with others like SC, TB, and VC, helps identify different types of oil seals based on their structural features and functions. This system aids engineers and procurement specialists in selecting the appropriate seal type, ensuring optimal performance for specific machinery requirements.

Symbolism of TC Oil Seals

The “T” and “C” in the TC seal code represent specific design features. The “T” typically refers to a particular structural shape, while the “C” indicates material composition or a functional aspect. This coding system makes it easier to distinguish TC seals from other types in the market.

3. What Does TG Mean on an Oil Seal?

Definition of TG Oil Seals

TG oil seals are often considered an alternative to TC oil seals, offering similar functions but with slight differences in design. The TG classification provides another standardized option for sealing applications, catering to specific installation or aesthetic needs.

Design Similarities with TC Oil Seals

The design, materials, and primary function of TG oil seals are almost identical to TC oil seals. Both types feature essential components like the sealing lip, garter spring, and metal casing, which ensures reliable sealing performance in various machinery applications.

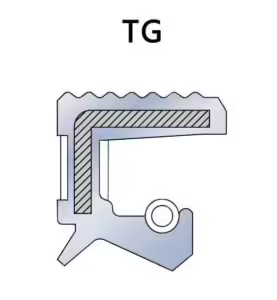

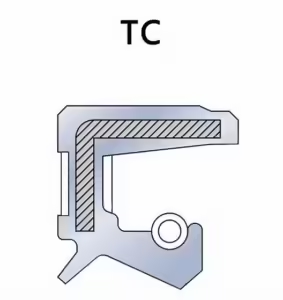

Key Difference Between TC and TG Oil Seals

The primary distinction between TC and TG oil seals is the outer diameter. TG seals feature a threaded outer diameter, making them easier to install compared to the smooth outer surface of TC seals. This threaded design can significantly reduce installation time and effort, particularly in environments that require frequent maintenance or seal replacement.

Color Variation of TG Oil Seals

In some markets, TG oil seals are produced in a brown color, enhancing their aesthetic appeal. This color difference makes TG seals more attractive to customers who value visual aspects, which can improve marketability and sales compared to the standard black TC oil seals.

4. Key Differences Between TC and TG Oil Seals

Design and Structure Comparison

Both TC and TG oil seals are designed with a sealing lip for fluid containment, a garter spring for maintaining pressure, and a durable metal case for added strength. These similarities ensure that both seals provide reliable sealing performance across various applications.

Outer Diameter and Installation Ease

TG oil seals feature a threaded outer diameter, offering a significant advantage in installation. This design simplifies the fitting process, making it faster and more secure compared to TC seals with a smooth outer surface, which requires more careful handling during installation.

Color Differences and Aesthetic Appeal

TC seals are typically black, whereas TG seals are often produced in brown, especially by certain manufacturers. This color difference not only affects the visual appearance but also influences consumer preferences, with brown TG seals being more popular in regions where a premium look is desired.

Materials and Performance

Both TC and TG oil seals are made from similar materials, such as nitrile rubber, silicone, or fluorocarbon. These materials provide excellent performance characteristics, including temperature resistance and chemical compatibility, ensuring comparable durability and functionality across various conditions.

Market Preferences

Market preferences may influence the choice between TC and TG seals. In markets where aesthetics play a significant role, brown TG seals may be more favored, increasing their marketability. Conversely, black TC seals are widely accepted and may be preferred in cost-sensitive regions due to their lower price point.

5. Advantages of TG Oil Seals Over TC Oil Seals

Easier Installation

The threaded outer diameter of TG seals simplifies the installation process, enabling quicker and more secure fitting, which is particularly advantageous in environments where maintenance is frequent and downtime is minimized.

Enhanced Aesthetic Appeal

The brown color of TG oil seals gives them a more premium and high-end appearance compared to the standard black TC seals. This can be a significant advantage in markets where the visual appeal of machinery components matters to customers.

Marketability and Pricing Strategy

In markets where TC oil seals face competition due to their lower price, transitioning to TG seals with a brown color can help reposition the product as a higher-end option. This strategy can improve customer perception and potentially increase sales by appealing to customers seeking both quality and aesthetics.

6. Common Applications of TC and TG Oil Seals

Automotive Industry

Both TC and TG oil seals are extensively used in the automotive sector, particularly in engines, transmissions, and pumps. They play a crucial role in maintaining the integrity of lubrication systems, preventing oil leaks, and ensuring optimal engine performance.

Industrial Machinery

In industrial machinery and manufacturing equipment, TC and TG seals are employed to protect critical components. Their reliable sealing capabilities help maintain operational efficiency and extend the lifespan of machinery.

Pumps and Compressors

TC and TG oil seals are essential in fluid, gas, and hydraulic systems in pumps and compressors, where they prevent leaks and ensure the smooth operation of these vital components, contributing to overall system reliability.

Harsh Environment Applications

Both TC and TG oil seals are designed to perform well in standard temperature and chemical conditions, making them suitable for a variety of industries. Their resilience in harsh environments ensures consistent performance and durability, even under demanding operational stresses.

7. Performance Characteristics of TC and TG Oil Seals

Temperature Resistance

Both TC and TG oil seals exhibit excellent temperature resistance, maintaining effective sealing performance in a wide range of temperatures, from high to low, without compromising their functionality.

Chemical Resistance

The materials used in both TC and TG oil seals provide excellent chemical compatibility with oils, lubricants, and a range of aggressive substances. This ensures the seals maintain their integrity and performance even when exposed to harsh chemicals.

Durability

Both TC and TG seals are durable, contributing to the overall longevity of machinery. Additionally, the easy installation feature of TG seals helps minimize downtime during repairs or replacements, improving operational efficiency.

8. When to Choose TC vs. TG Oil Seals

Price Sensitivity

For cost-sensitive applications, TC oil seals are typically the more affordable choice. However, if a market demands higher-end options, TG oil seals, especially those with a brown color, can be a more attractive choice, offering both quality and aesthetics at a slightly higher price point.

Installation Considerations

If ease of installation is crucial, TG oil seals with their threaded outer diameter are the better option. Their design allows for faster and more secure fitting, making them ideal for environments where quick installations and replacements are required.

Industry-Specific Requirements

Different industries have unique needs based on their applications. For example, the automotive sector may prioritize durability and chemical resistance, while industries involving heavy machinery may focus on ease of installation and overall longevity.

9. Conclusion

While TC and TG oil seals share many similarities in design and performance, the key differences in their outer diameter, color, and installation features make them suitable for different applications. Understanding these differences helps businesses make informed decisions when selecting the right oil seal, ensuring optimal machinery performance and meeting specific market demands.

10. Contact Information

For more information or inquiries about our oil seals, please reach out to us through the following channels:

- Website: drorubber.com

- WhatsApp: +0086 15815831911

- WeChat: +0086 13784044874