Which Way Does a Shaft Seal Go? A Complete Guide to Proper Installation

Introduction

In a wide range of machinery and equipment, the shaft seal (also known as an oil seal) is a crucial component. It plays a pivotal role in preventing lubricants, such as oil or grease, from leaking out, while simultaneously keeping contaminants like dust and water from entering. An improperly installed shaft seal can lead to reduced performance, premature equipment failure, and costly downtime. Understanding the correct orientation of a shaft seal is therefore essential to ensuring optimal equipment operation and longevity.

Understanding the Shaft Seal’s Purpose and Design

- The Function of a Shaft Seal

Shaft seals serve two primary purposes:- Retaining internal media: They keep valuable lubricants inside the system, preventing oil leakage and maintaining proper lubrication conditions.

- Blocking external contaminants: They also shield the internal components from external pollutants such as dirt, dust, and moisture, protecting bearings and other sensitive parts.

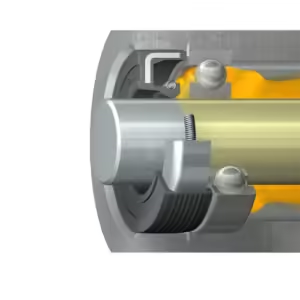

- Key Components of a Shaft Seal

- Sealing Lip: The flexible lip creates a tight seal against the shaft surface.

- Outer Casing (Body): Provides structural stability and ensures a secure fit within the housing.

- Spring (If Present): Some seals include a garter spring to maintain consistent pressure on the sealing lip, enhancing sealing efficiency.

Determining the Correct Orientation of a Shaft Seal

- The Basic Installation Rule: Lip Towards the Medium to Retain

The sealing lip should always face the fluid or material it is intended to hold back. For lubricants like oil, the lip should face inward, toward the lubricant. For environments where the primary goal is to prevent contamination, the lip should face outward, toward the source of contaminants. - Installation Scenarios

- Oil Retention: If the seal is installed in an environment where the goal is to retain oil or grease, the lip faces inward.

- Contamination Prevention: If the seal is intended to keep out external contaminants, the lip should face outward, toward the direction of potential ingress.

- Combination Seals: Some seals are designed with dual lips, one facing inward and one facing outward, to handle both retention and contamination simultaneously.

- Visual Inspection Tips

- Spring Side Indication: If a garter spring is present, it typically indicates the side facing the medium you want to retain.

- Markings or Arrows: Certain seals may have directional markings or arrows. Always follow these indicators to ensure proper orientation.

The Importance of Using Lubrication During Installation

- Protecting the Sealing Lip

Before installing the seal, applying a thin layer of grease or oil to the sealing lip is highly recommended when conditions allow. This lubrication reduces friction and prevents damage to the lip during the pressing-in process. - DRO’s Professional Lubrication Service

At DRO, we recognize the importance of proper lubrication. For your convenience, we offer professional pre-lubrication services. We can apply a suitable layer of grease to the shaft seal before delivery, ensuring easier installation and enhanced performance right from the start.

- Protecting the Sealing Lip

Common Mistakes and How to Avoid Them

- Reversed Orientation

Installing the seal backwards can result in immediate leakage, seal damage, and premature failure. Always double-check the correct orientation before installation. - Excessive Force or Improper Tools

Using the wrong tools or applying too much force can deform the seal or damage its lip. A gentle, even pressure is key to maintaining the seal’s integrity. - Neglecting Cleanliness

Ensure the shaft and housing are clean, free of debris, and without scratches. Contaminants or surface irregularities can compromise the seal’s ability to form an effective barrier.

Step-by-Step Installation Guide

- Inspect and Clean: Verify that the shaft and housing are clean and dimensionally correct.

- Apply Lubrication: Lubricate the sealing lip with a thin layer of grease or oil (if not already pre-lubricated by DRO).

- Correct Orientation: Position the seal so that the lip faces the appropriate direction—toward the fluid to be retained or the contamination source to be excluded.

- Press In Evenly: Gently press the seal into the housing, ensuring even pressure and avoiding misalignment.

- Post-Installation Check: Confirm that the seal sits properly and that the lip is undamaged and aligned correctly.

Conclusion

Proper installation of a shaft seal is critical to maintaining its sealing effectiveness and ensuring the longevity of your machinery. By following the basic orientation rule, applying appropriate lubrication, and avoiding common errors, you can maximize seal performance and extend equipment life.

Call to Action

For premium-quality rubber shaft seals and a variety of sealing solutions, visit drorubber.com. If you need expert guidance or custom solutions, feel free to contact us via:

- WhatsApp: +0086 15815831911

- WeChat: +0086 13784044874

Let DRO’s professional sealing products and services support the efficiency and reliability of your equipment.