Overview of O-Ring Manufacturing Materials

Introduction

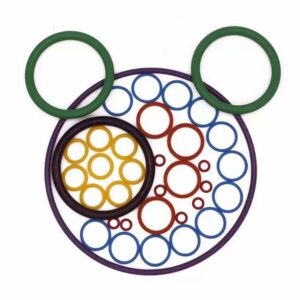

O-rings are essential sealing components used across a multitude of industries, including automotive, aerospace, medical, and manufacturing. These simple yet effective rings prevent the leakage of fluids and gases, ensuring the integrity and efficiency of various systems and machinery. The performance and longevity of an O-ring heavily depend on the material from which it is made. Selecting the right material is crucial, as it must withstand specific environmental conditions and meet stringent performance requirements tailored to its intended application.

1. Common O-Ring Materials

NBR (Nitrile Butadiene Rubber)

General Properties:

Nitrile Butadiene Rubber (NBR) is one of the most versatile and cost-effective materials used in O-ring production. It is widely favored for its excellent mechanical properties and resistance to oil and fuel.

Ideal Applications:

NBR is commonly used in automotive engines, industrial machinery, and general sealing applications where exposure to oils and hydraulic fluids is prevalent.

Performance Characteristics:

NBR exhibits excellent resistance to a wide range of oils, fuels, and hydraulic fluids, making it suitable for environments where these substances are present.

Pros:

- Affordable and readily available

- Reliable performance in most environments

- Good mechanical strength and durability

Cons:

- Limited high-temperature performance

- Poor resistance to weathering and ozone, which can lead to degradation over time

FKM (Fluorocarbon Rubber)

General Properties:

Fluorocarbon Rubber (FKM), also known by brand names like Viton®, offers exceptional resistance to high temperatures, oils, fuels, and various chemicals. It is a high-performance material suitable for demanding applications.

Ideal Applications:

FKM is ideal for use in automotive and aerospace industries, chemical processing plants, and industrial systems exposed to high temperatures and aggressive chemicals.

Performance Characteristics:

FKM maintains its integrity and performance in high-temperature environments and provides excellent chemical resistance against a wide array of substances.

Pros:

- Superior resistance to heat, ozone, and chemical exposure

- Excellent durability under harsh conditions

Cons:

- Higher cost compared to other materials

- Can become brittle at extremely low temperatures, limiting its use in cold environments

SIL (Silicone Rubber)

General Properties:

Silicone Rubber (SIL) is renowned for its flexibility and ability to perform in extreme temperatures. It is non-toxic and biocompatible, making it suitable for specialized applications.

Ideal Applications:

SIL is widely used in the food processing industry, medical devices, and water-based applications where safety and flexibility are paramount.

Performance Characteristics:

Silicone offers excellent temperature resistance, maintaining flexibility in both high and low-temperature extremes. However, it has poor resistance to oils and fuels, limiting its use in certain environments.

Pros:

- Exceptional temperature flexibility

- Inert and safe for food and medical use

- Highly flexible and easy to install

Cons:

- Limited chemical and oil resistance

- Not suitable for applications involving hydrocarbons or other aggressive chemicals

2. Other Notable O-Ring Materials

HNBR (Hydrogenated Nitrile Butadiene Rubber)

General Properties:

Hydrogenated Nitrile Butadiene Rubber (HNBR) is a hydrogenated version of NBR, offering enhanced resistance to heat, oxidation, and ozone. This makes it a superior choice for demanding applications.

Ideal Applications:

HNBR is ideal for use in refrigeration systems, automotive components, and industrial equipment that require high durability in harsh environments.

Performance Characteristics:

HNBR provides excellent low-temperature flexibility and performs well under high-pressure conditions, making it suitable for applications that involve significant mechanical stress.

Pros:

- Enhanced heat and wear resistance compared to standard NBR

- High-performance characteristics suitable for demanding environments

Cons:

- More expensive than standard NBR

- Primarily used in high-end applications due to its cost

EPDM (Ethylene Propylene Diene Monomer)

General Properties:

Ethylene Propylene Diene Monomer (EPDM) rubber is known for its outstanding resistance to weathering, ozone, and ultraviolet (UV) exposure. It is a synthetic rubber that performs exceptionally well in outdoor applications.

Ideal Applications:

EPDM is commonly used for sealing in HVAC systems, automotive weather stripping, and other outdoor or weather-exposed systems.

Performance Characteristics:

EPDM offers excellent resistance to acids, bases, and various environmental factors, making it a reliable choice for outdoor and weather-exposed applications.

Pros:

- Excellent for outdoor applications and systems exposed to extreme weather

- Great resistance to UV radiation, ozone, and aging

Cons:

- Poor resistance to oils, fuels, and solvents

- Limited use in applications involving hydrocarbons

3. Advanced O-Ring Materials

FFKM (Perfluoroelastomer)

Properties & Composition:

Perfluoroelastomer (FFKM) is a high-performance material used in the most demanding environments. It offers exceptional chemical resistance, particularly against aggressive acids, bases, solvents, and oxidative agents.

Performance Characteristics:

FFKM can withstand extreme temperatures ranging from -40°C to +330°C (or higher in certain formulations). It excels in applications involving extreme pressures and aggressive chemical exposures.

Applications:

FFKM is primarily used in industries such as petrochemical, semiconductor, aerospace, pharmaceuticals, and food processing. It is essential for sealing critical systems like valves, pumps, and equipment in high-tech industries.

Pros:

- Unmatched chemical and temperature resistance

- Long lifespan in extreme conditions, reducing downtime and maintenance costs

Cons:

- Expensive, making it suitable primarily for high-end industrial applications with strict performance requirements

4. Specialized O-Ring Materials for Extreme Environments

FFKM for Semiconductor and Aerospace Industries

Specific Benefits:

In highly demanding environments such as vacuum chambers and aerospace propulsion systems, FFKM O-rings provide reliable sealing under extreme conditions. Their ability to maintain integrity in high-pressure and high-temperature scenarios makes them indispensable in these sectors.

Real-World Applications and Case Studies:

For instance, in semiconductor manufacturing, FFKM O-rings ensure the purity and precision required in vacuum systems. Similarly, in aerospace, they are used in propulsion systems where failure is not an option, ensuring the safety and efficiency of space missions.

High-Performance O-Rings for Oil & Gas and Petrochemical Sectors

Material Focus:

Materials like FFKM, HNBR, and FKM are designed for high chemical and pressure resistance, making them ideal for the oil and gas industries.

Sealing Solutions:

These O-rings are used in drilling equipment, pipelines, and oilfield machinery, where they must withstand harsh chemicals, high pressures, and extreme temperatures. Their durability and reliability are critical for maintaining system integrity and preventing leaks in these high-stakes environments.

5. Factors to Consider When Selecting O-Ring Materials

Temperature Resistance

Importance:

The ability of an O-ring material to tolerate high and low temperatures is crucial. Materials must maintain their elasticity and sealing properties without degrading under thermal stress.

Impact on Selection:

Depending on the operating conditions, selecting a material with appropriate temperature tolerance ensures longevity and reliable performance. For instance, SIL is preferred for applications with extreme temperature variations, while FKM is chosen for high-temperature environments.

Chemical Compatibility

Significance:

Choosing the right O-ring material based on the specific chemicals it will encounter is vital to prevent degradation and failure.

Considerations:

Materials must be compatible with the fluids or gases they will seal. For example, NBR is suitable for oil-based applications, while FFKM is necessary for environments with aggressive chemicals.

Pressure and Mechanical Properties

Understanding Performance:

O-ring materials must perform well under the pressure and mechanical stresses of their application. This includes resistance to deformation, compression set, and mechanical wear.

Selection Process:

Materials like HNBR and FKM are preferred in high-pressure applications due to their superior mechanical properties and ability to maintain sealing integrity under stress.

Environmental Resistance

Impact of Environmental Factors:

Exposure to weathering, UV radiation, ozone, and other environmental factors can affect the longevity of O-rings.

Material Longevity:

Selecting materials like EPDM for outdoor applications ensures resistance to environmental degradation, while materials like FKM provide resistance to ozone and chemical exposure.

6. Conclusion

Selecting the appropriate O-ring material is a critical decision that impacts the performance, durability, and reliability of sealing solutions across various industries. This article has explored common materials such as NBR, FKM, and SIL, as well as advanced options like FFKM and specialized materials like HNBR and EPDM. Each material offers unique properties that make it suitable for specific applications, considering factors like temperature resistance, chemical compatibility, mechanical properties, and environmental exposure.

Final Advice:

When selecting an O-ring material, it is essential to consider the specific application requirements, including performance needs, environmental conditions, and budget constraints. Balancing these factors ensures the selection of the most effective and cost-efficient material for your sealing needs.

Call to Action

For tailored recommendations and expert guidance on selecting the ideal O-ring material for your specific application, consult with industry professionals. Additionally, high-quality O-rings for specialized applications can be sourced from reputable suppliers who offer a wide range of materials to meet diverse sealing requirements.