Should I Select a Seal with a Metal Case or Rubber OD?

Introduction

In industrial applications, choosing the right oil seal design is crucial for the efficiency and longevity of machinery. Oil seals prevent lubricants from leaking and contaminants from entering, playing a vital role in maintaining equipment performance. Two primary options are available: seals with metal cases (exposed metal outer diameter) and seals with rubber outer diameters (rubber OD). Popular models include TB, SB, TA, SBB for metal case seals, and TC, TG, SC, KC for rubber OD seals. This article compares these two types based on performance, cost, versatility, and application scenarios to help you make an informed decision.

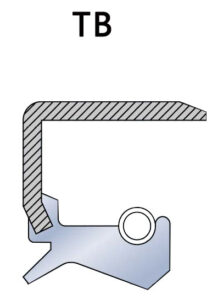

1. What Is an Oil Seal with a Metal Case (Exposed Outer Diameter)?

Definition and Design

An oil seal with a metal case features an exposed outer diameter made entirely of metal. The structure includes a rigid metal casing that provides mechanical support and stability. The sealing lip, usually made of elastomeric material like nitrile rubber or fluorocarbon, ensures a tight seal against the rotating shaft.

Advantages

- Heat Dissipation: Metal conducts heat efficiently, making these seals ideal for high-temperature applications where excessive heat could compromise seal integrity.

- Dimensional Stability: The rigid metal outer case offers excellent mechanical stability, maintaining its shape under high-pressure environments and resisting deformation.

Applications

Metal case seals are commonly used in heavy machinery, high-speed rotating equipment, and scenarios with high thermal loads. They are suitable for environments where durability and heat management are critical.

Common Models: TB, SB, TA, SBB, etc.

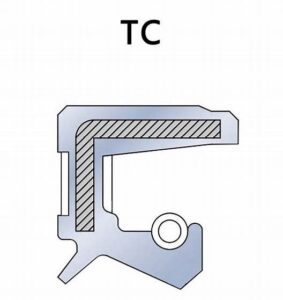

2. What Is an Oil Seal with a Rubber OD (Fully Covered Outer Diameter)?

Definition and Design

A rubber OD seal features a metal skeleton completely encased in rubber on the outer diameter. The rubber coating covers the entire exterior, allowing for a more adaptable and flexible fit into the housing bore. The sealing lip is also made of rubber or similar elastomeric materials.

Advantages

- Sealing Flexibility: The rubber exterior compensates for minor imperfections or irregularities in the housing surface, ensuring a better seal even when the mating surface isn’t perfectly smooth.

- Versatility: Available in a wide variety of models and sizes, rubber OD seals are compatible with numerous applications across different industries.

- Lower Cost: Due to mass production and standardization, rubber OD seals are generally more affordable than their metal-cased counterparts.

Applications

These seals are suitable for automotive applications, light machinery, and general industrial use. They are ideal for standard sealing needs where extreme conditions are not a factor.

Common Models: TC, TG, SC, KC, etc.

3. Key Differences Between Metal Case and Rubber OD Seals

Heat Dissipation

- Metal Case Seals: Excel in dissipating heat, making them ideal for high-temperature environments.

- Rubber OD Seals: Less efficient at heat dissipation but adequate for applications with moderate temperatures.

Sealing Effectiveness

- Rubber OD Seals: Provide superior sealing performance on housings with minor surface imperfections due to the flexible rubber coating.

- Metal Case Seals: Require precise housing surfaces for effective sealing, as the rigid metal cannot compensate for irregularities.

Durability

- Metal Case Seals: Offer high mechanical strength, suitable for extreme pressure and heavy-duty applications.

- Rubber OD Seals: Provide sufficient durability for most standard applications but may not withstand as much mechanical stress.

Cost and Availability

- Rubber OD Seals: More affordable and widely available due to mass production.

- Metal Case Seals: Generally more expensive and used in specialized applications.

4. When Should You Choose a Metal Case Seal?

Consider metal case seals in the following situations:

- High-Temperature Environments: Where efficient heat dissipation is necessary.

- High Pressure or Mechanical Loads: In applications subjected to extreme pressures or stresses.

- Precision-Machined Housings: When housing surfaces are precise with minimal imperfections.

5. When Should You Choose a Rubber OD Seal?

Rubber OD seals are preferred in these scenarios:

- Housing Imperfections: When the housing bore has minor imperfections requiring flexible sealing.

- Standard Applications: Suitable for automotive, light machinery, and general industries.

- Cost-Sensitive Projects: Where affordability and versatility are key factors.

6. Conclusion

Selecting between a metal case seal and a rubber OD seal depends on your specific application requirements. Metal case seals offer superior heat dissipation and mechanical strength, ideal for high-temperature and high-pressure environments with precise housings. Rubber OD seals provide better sealing on imperfect surfaces, greater versatility, and cost-effectiveness, making them suitable for standard applications.

Consider factors like heat dissipation needs, mechanical stress, sealing performance, and budget when making your decision. Consulting with professionals or suppliers can provide additional insights tailored to your needs.

7. Call-to-Action

For expert advice on selecting the right oil seal, feel free to consult with our team. We offer an extensive inventory of both metal case seals and rubber OD seals, including popular models like TB, SB, TC, and KC. Contact us at:

- Phone: [ +008613784044874]

- Email: [[email protected]]

- Website: [drorubber.com]

Our technical support team is ready to assist you in finding the perfect sealing solution for your applications.