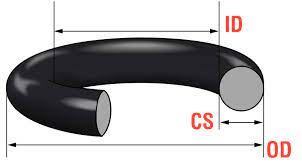

DRO has a wide range of mold sizes, with the inner diameter starting from 1mm to 5000mm,

all of which can be produced.

CS SIZE:

American AS568:1.02 / 1.2 / 1.78 / 2.62 / 3.53 / 5.33 / 6.99(mm)

ChinaGB/T 3452.1-2005:1 / 1.2 / 1.8 / 2.65 / 3.1 / 3.55 / 4 / 5 / 5.3 / 5.7 / 7 / 8.6(mm)

The above wire diameters are in stock at DRO. Please contact us for details.

Due to the high temperature resistance, chemical resistance and oil resistance of fluororubber O-rings, they are widely used in various industrial and high-end applications.

However, fluororubber has poor low temperature performance, so you should pay attention to this when choosing.

Nitrile rubber O-ring has good oil resistance, wear resistance and compression resistance, and is an economical and widely used sealing material.

It has extremely high application value in industries that require oil seals, such as hydraulic equipment and machinery manufacturing.

Silicone sealing rings are an ideal choice for high-demand industries such as food, medical, and electronics due to their excellent high and low temperature resistance, elasticity, aging resistance, and hygienic safety.

However, they have poor oil resistance and cannot be used in some oil environments.

FFKM rubber is widely used in demanding industrial and technical fields due to its extreme chemical resistance and high temperature resistance.

Although it is expensive, it provides unparalleled sealing effect in applications that require long-term high temperature, high pressure, and highly corrosive environments.

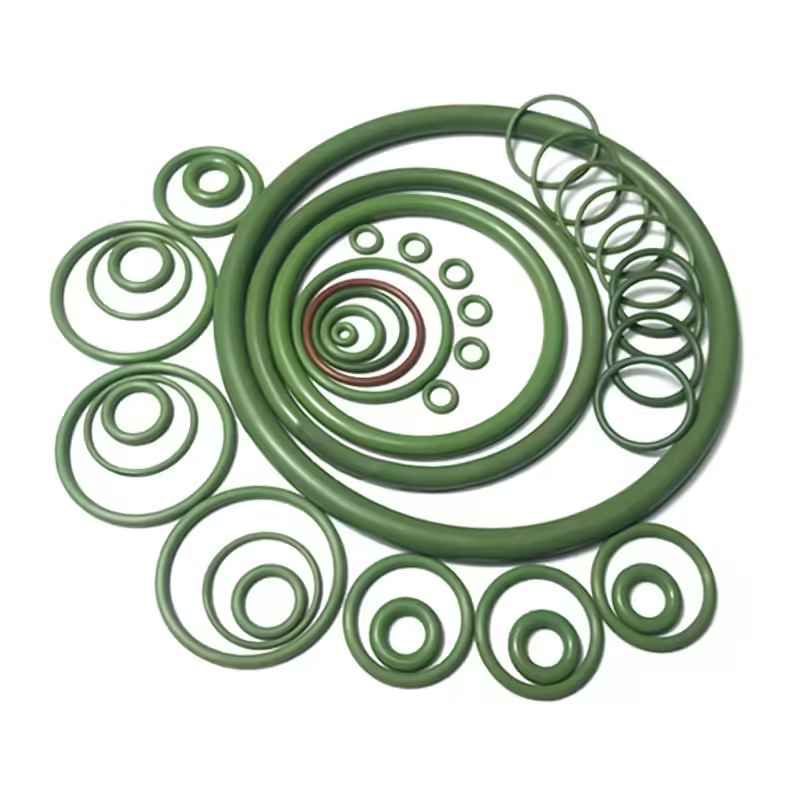

This is the HNBR O-ring we have been selling for automotive refrigeration systems.

Of course,as well as O-rings designed to withstand extremely cold temperatures, capable of handling temperatures as low as -50°C.

Currently, we are selling O-ring kits, including those for heavy-duty vehicles and excavators (such as Komatsu, Hitachi, Kobelco, SANY, etc.),

and we also have stock available for excavators with a 90 hardness.We have all of them in stock.

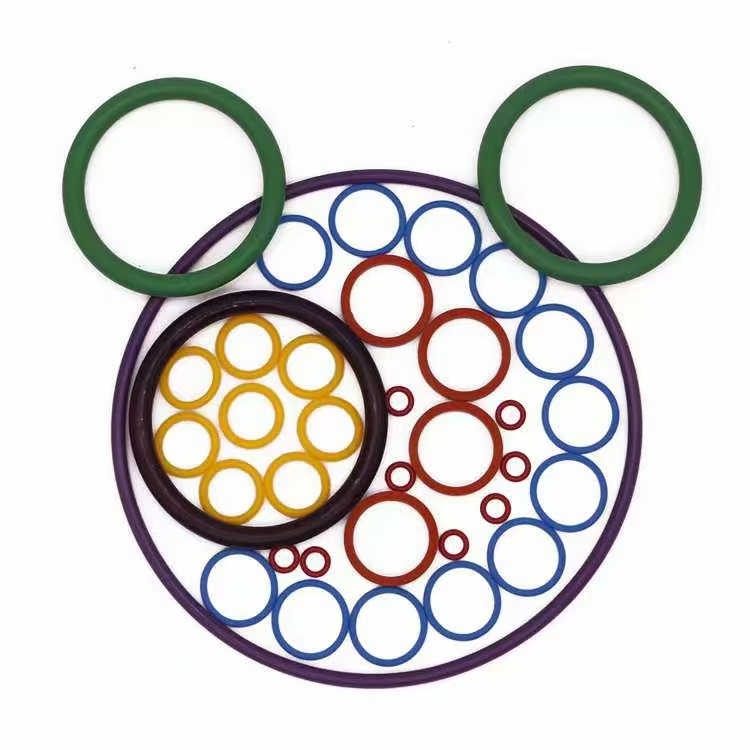

We can compound any rubber, including NBR, FKM, EPDM, and SIL,into any color.

As long as you provide a sample, we can match the color you need. This is our expertise.And we can fully match the performance as well.

We can produce products of any wire diameter and any size,

thanks to our mastery of hot-joining technology.

This is a technological breakthrough, and there is no doubt about its excellent performance.

At DRO, the unique needs of your project drive our customization process. Not only do we carry a large inventory of standard seals, we are your personal custom concierge, custom-making seals to the exact specifications of your project. Here’s how we meet your unique requirements:

High stock levels:We have over one million seals in stock of various materials to meet your urgent needs

Diverse material options:We offer in a variety of materials for you to choose from, ensuring that they meet the specific needs of your industry.

Optimized Performance:Our raw material suppliers include DuPont, Solvay, Daikin and other internationally renowned manufacturers, allowing you to flexibly choose the perfect configuration for your application needs to optimize performance and durability

Tight tolerances:The precision of mold size is a link that we have always strictly controlled. Our own CNC mold room ensures product tolerance.

There are many types of rubber on the market, such as

NBR/FKM/SIL/EPDM/

FFKM/CR/NR…..

NBR rubber is widely used due to its excellent oil resistance, especially for contact with petroleum-based oils, fuels and lubricants. The main feature of this rubber is its excellent resistance to oil products, which makes it an ideal choice for oil seals, fuel system seals and hoses in the automotive industry. In the aerospace industry, NBR is often used to treat seals in fuel and lubrication systems. In addition, nitrile rubber also has good wear resistance and mechanical properties, suitable for environments that require high strength and friction resistance.

FKM rubber is a high-performance fluorochemical rubber with extremely high chemical resistance and high temperature resistance. It is widely used in aerospace, chemical, automotive and petroleum industries. FKM has outstanding chemical stability and can resist corrosion from most strong acids, strong alkalis, fuels, solvents and other corrosive chemicals. This rubber is particularly suitable for use in harsh environments, such as seals in chemical equipment, pipe sealing systems in oil drilling, and high-temperature seals in aircraft engine components.

Another advantage of FKM rubber is its high temperature resistance. It can maintain good physical properties in the temperature range of -20°C to +200°C. Some special formulas can even withstand extreme temperatures of up to 300°C.

Silicone rubber is a high-performance synthetic rubber known for its resistance to extreme temperatures, non-toxicity, odorlessness, and electrical insulation properties. Silicone rubber can operate in a wide temperature range of -60°C to +250°C, which makes it important in high-temperature applications, especially in the automotive, electronics, and household appliances industries. In addition, silicone rubber is also very chemically inert and has good tolerance to water, polar solvents, and many chemicals. It is widely used in food processing, medical devices, and other fields, and can come into direct contact with the human body or food.

Silicone rubber also has excellent electrical insulation properties, so it is very common in electronic and electrical applications, such as high-temperature cable sheaths and electronic equipment seals. Silicone rubber also has good UV and ozone resistance, so it can maintain physical properties for a long time in outdoor applications. However, silicone rubber has relatively weak mechanical strength and wear resistance, and is not oil-resistant, so it is not suitable for occasions where it comes into contact with oils and fuels.

EPDM rubber is favored for its excellent anti-aging and weather resistance, especially in outdoor applications. EPDM rubber can be exposed to ozone, ultraviolet rays and extreme climate conditions for a long time without showing obvious aging, cracking or hardening. This makes it the material of choice for building waterproofing materials, automotive sealing strips and cable sheathing. In addition, EPDM has excellent elasticity at extreme temperatures and can maintain good physical properties in the range of -50°C to +150°C. Therefore, it is widely used in the automotive industry, roof waterproofing, and electrical insulation.

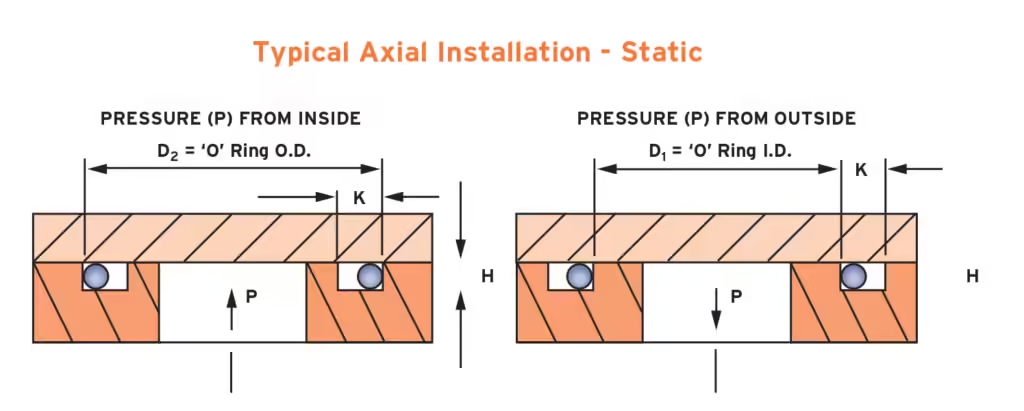

Although the installation of O-rings seems simple, it is very important to install them correctly to ensure their sealing performance and durability during use.

Clean the mounting surface: Before installing the O-ring, make sure the mounting surface and the O-ring itself are clean and free of dust, dirt or debris.

Inspect the O-ring: Carefully inspect the O-ring for damage, cracks or nicks to ensure it is in good condition.

Try to avoid over-stretching the O-ring during installation, especially when the O-ring needs to slide over threads, corners or sharp edges. If stretching is required, the stretch rate should generally not exceed 5% of its unstretched state.

O-rings are usually designed to be compressed to a certain extent to perform their sealing function. The amount of compression needs to be determined according to the material, hardness and application environment of the O-ring. The general compression rate is around 15%-30%.