Improve Your Sealing Performance with DRO’s Custom Solutions & OEM/ODM Services

As a leading seal manufacturer, DRO has the ability to produce any type of seals in any material, whether it is oil seals, O-rings or sealing gaskets. Our excellent mold development capabilities and material control ensure that every seal can play an excellent sealing performance.

There are many types of rubber materials, and the most common ones on the market are NBR / FKM (VITON) / SILICONE / EPDM / CR / NR / FFKM. Next, we will introduce the specific uses of these rubbers in detail.

This is an oil seal made of fluororubber. Fluororubber can withstand high temperatures of 230 degrees Celsius and has excellent wear resistance.Under certain circumstances, the speed can even reach 25,000 rpm. Of course, the price is also relatively expensive.

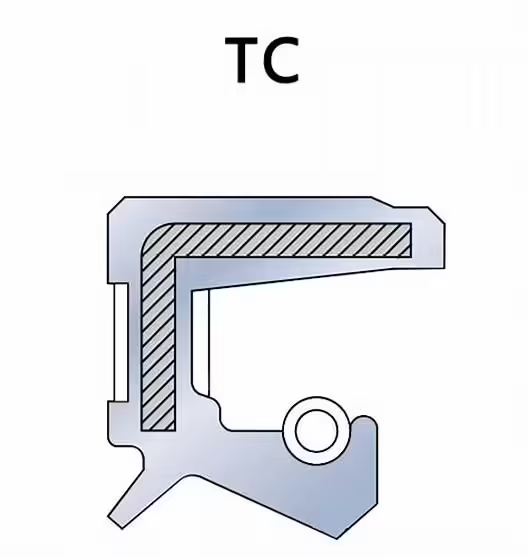

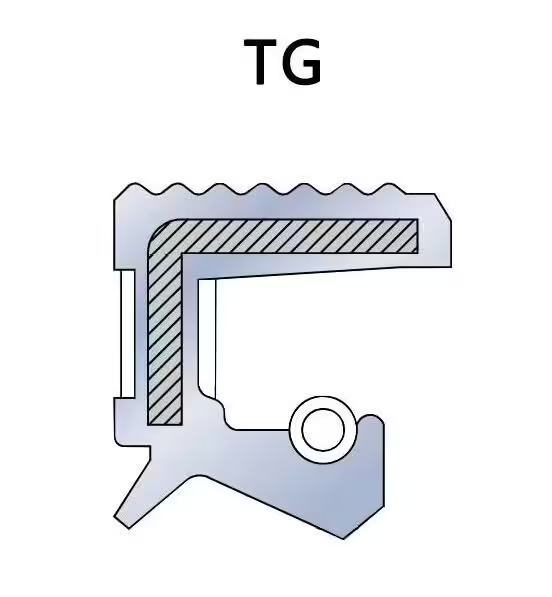

The difference between this model and the previous one is that the outer contact surface of TC is smooth, while TG is threaded.

The appearance is different, but the internal structure is indeed the same, and the actual use scenarios and effects are also the same.

This is an oil seal made of nitrile rubber. Nitrile rubber can withstand 120 degrees Celsius and has excellent oil and wear resistance.

High cost performance is the advantage of nitrile rubber. Of course, this is also the most common civilian rubber on the market.

The biggest feature of NBR oil seals is their strong resistance to petroleum-based oils.

They have excellent oil resistance to mineral oils, fuel oils, lubricating oils, etc., so they are widely used in situations where oil leakage needs to be prevented.

The design concept of the MC oil seal is to protect the rotating shaft from damage caused by wear at the lip during movement.

This oil seal is a split-type seal, and it rotates automatically when the shaft moves.It is particularly suitable for the central shaft of rotary tillers

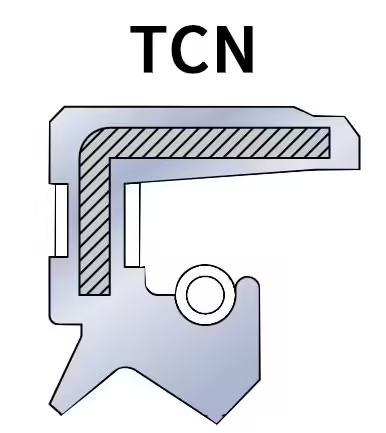

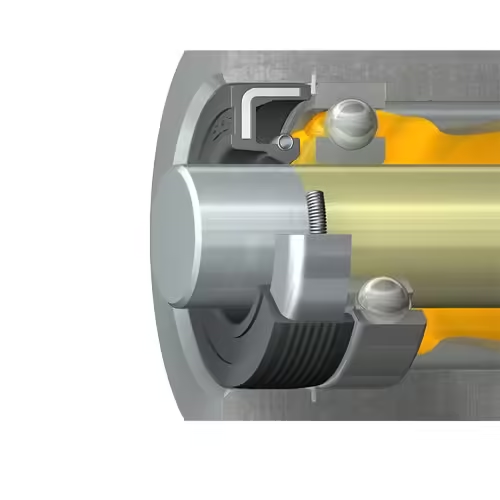

TCN high-pressure oil seals are designed to withstand extreme pressure conditions, making them ideal for applications such as hydraulic systems, automotive engines, gearboxes, and industrial machinery. ensuring the efficient and reliable operation of equipment.

outer skeleton oil seals provide superior sealing, heat dissipation, and shock resistance. Their metal outer frame enhances strength, durability, and reliability in demanding applications, including mechanical equipment, mining machinery, and oil drilling operations.

EC oil seal is primarily designed for housing seals, specifically for dust protection. It is typically used as an end cap seal,

focusing on preventing dust and contaminants from entering the equipment, ensuring smooth operation and extending service life

At DRO, the unique needs of your project drive our customization process. Not only do we carry a large inventory of standard seals, we are your personal custom concierge, custom-making seals to the exact specifications of your project. Here’s how we meet your unique requirements:

High stock levels:We have a full range of TC/TG models and materials in stock.

Diverse material options:We offer in a variety of materials for you to choose from, ensuring that they meet the specific needs of your industry.

Optimized Performance:Our raw material suppliers include DuPont, Solvay, Daikin and other internationally renowned manufacturers, allowing you to flexibly choose the perfect configuration for your application needs to optimize performance and durability

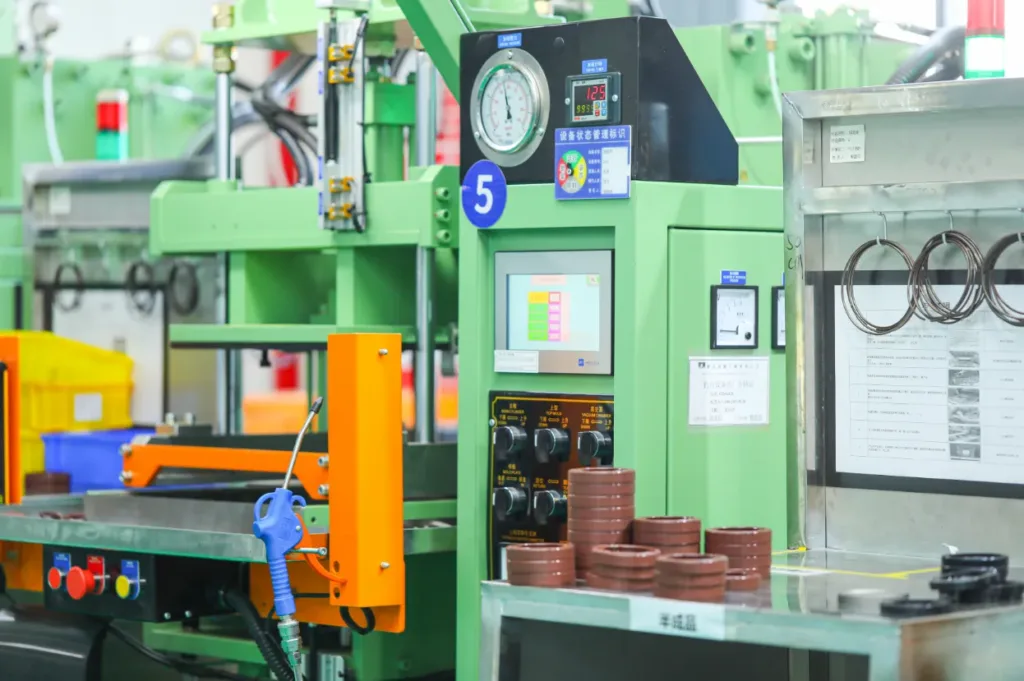

Tight tolerances:The precision of mold size is a link that we have always strictly controlled. Our own CNC mold room ensures product tolerance.

DRO is a leader in the sealing industry, providing more than just quality sealing solutions; we provide a partnership that helps your business succeed.

Our commitment to quality and deep industry expertise are the cornerstones of our services, ensuring your projects thrive.

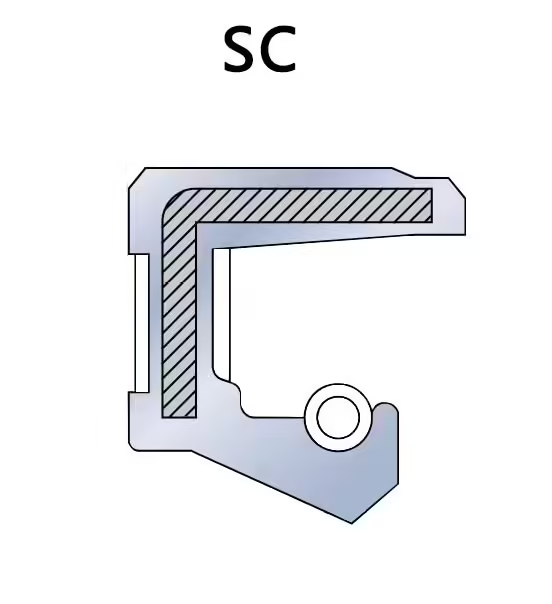

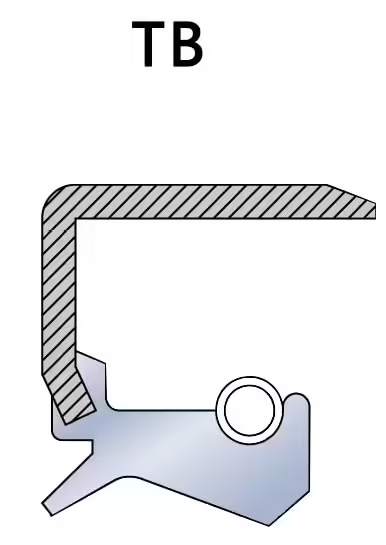

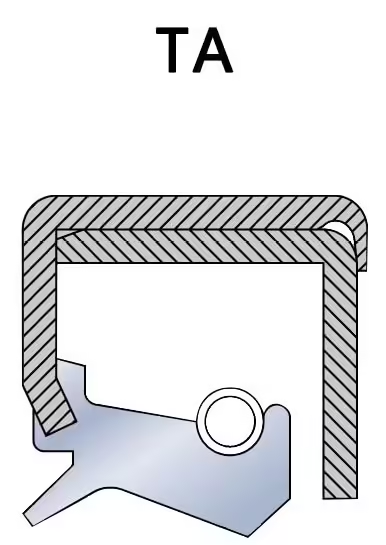

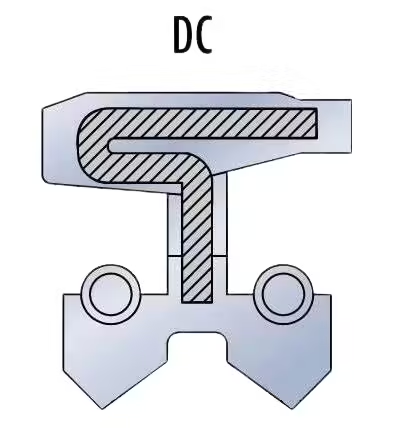

There are many types of oil seals, which can be divided into many types according to different application scenarios and material requirements.

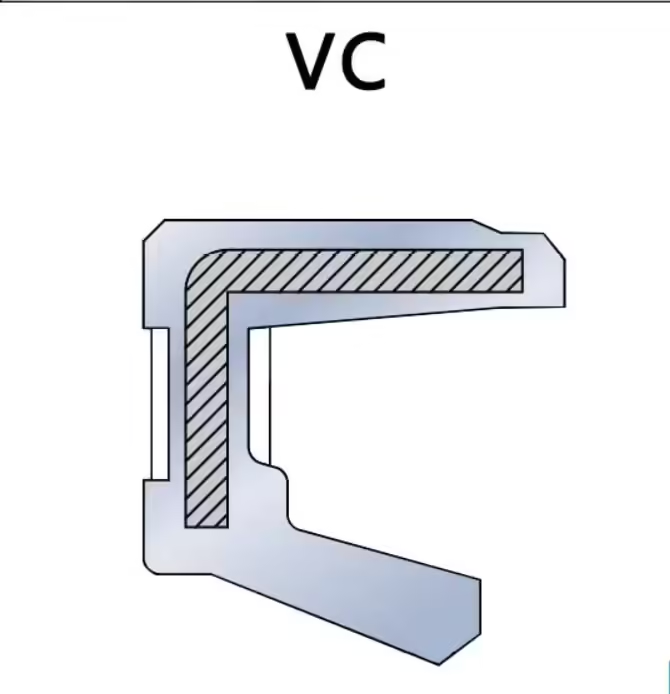

Common types of oil seals include:TC/SC/TG/TB/TCV/TA/DC/VC…..

According to different application environments, choosing the right oil seal type can ensure stable operation of the equipment and effective sealing of the liquid.

Check the oil seal and rotating shaft: make sure the skeleton oil seal and rotating shaft are not damaged or deformed, and the surface is smooth and free of burrs.

Lubricate the lip: Apply oil or grease compatible with the system to the lip of the oil seal and the shaft surface it contacts. This can reduce friction during installation.

The opening part of the oil seal (lip direction) should face the medium to be sealed (usually oil, liquid, etc.), and the outer frame should face outward. If installed in reverse, it may not be able to seal effectively, resulting in leakage.

There are many types of rubber on the market, such as

NBR/FKM/SIL/EPDM/

FFKM/CR/NR…..

NBR rubber is widely used due to its excellent oil resistance, especially for contact with petroleum-based oils, fuels and lubricants. The main feature of this rubber is its excellent resistance to oil products, which makes it an ideal choice for oil seals, fuel system seals and hoses in the automotive industry. In the aerospace industry, NBR is often used to treat seals in fuel and lubrication systems. In addition, nitrile rubber also has good wear resistance and mechanical properties, suitable for environments that require high strength and friction resistance.

FKM rubber is a high-performance fluorochemical rubber with extremely high chemical resistance and high temperature resistance. It is widely used in aerospace, chemical, automotive and petroleum industries. FKM has outstanding chemical stability and can resist corrosion from most strong acids, strong alkalis, fuels, solvents and other corrosive chemicals. This rubber is particularly suitable for use in harsh environments, such as seals in chemical equipment, pipe sealing systems in oil drilling, and high-temperature seals in aircraft engine components.

Another advantage of FKM rubber is its high temperature resistance. It can maintain good physical properties in the temperature range of -20°C to +200°C. Some special formulas can even withstand extreme temperatures of up to 300°C.

Silicone rubber is a high-performance synthetic rubber known for its resistance to extreme temperatures, non-toxicity, odorlessness, and electrical insulation properties. Silicone rubber can operate in a wide temperature range of -60°C to +250°C, which makes it important in high-temperature applications, especially in the automotive, electronics, and household appliances industries. In addition, silicone rubber is also very chemically inert and has good tolerance to water, polar solvents, and many chemicals. It is widely used in food processing, medical devices, and other fields, and can come into direct contact with the human body or food.

Silicone rubber also has excellent electrical insulation properties, so it is very common in electronic and electrical applications, such as high-temperature cable sheaths and electronic equipment seals. Silicone rubber also has good UV and ozone resistance, so it can maintain physical properties for a long time in outdoor applications. However, silicone rubber has relatively weak mechanical strength and wear resistance, and is not oil-resistant, so it is not suitable for occasions where it comes into contact with oils and fuels.

EPDM rubber is favored for its excellent anti-aging and weather resistance, especially in outdoor applications. EPDM rubber can be exposed to ozone, ultraviolet rays and extreme climate conditions for a long time without showing obvious aging, cracking or hardening. This makes it the material of choice for building waterproofing materials, automotive sealing strips and cable sheathing. In addition, EPDM has excellent elasticity at extreme temperatures and can maintain good physical properties in the range of -50°C to +150°C. Therefore, it is widely used in the automotive industry, roof waterproofing, and electrical insulation.