8000+ customers choose our customization,

precise size and excellent material

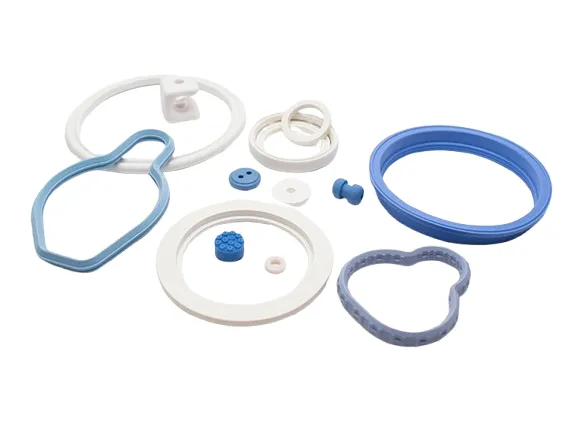

PTFE (Polytetrafluoroethylene), commonly known as Teflon, is a high-performance polymer with extremely stable chemical properties. Its carbon-fluorine bonds are exceptionally strong, making it highly resistant to chemical reactions.

Laser cutting technology,

no need to make molds,

more accurate size and lower cost

Rubber protective sleeves are a kind of protective product used to wrap and protect equipment and components. It can effectively prevent external factors such as dust and corrosion from damaging internal components. Common rubber protective sleeve products include automobile shaft head protective sleeves, mechanical seal sleeves, electronic equipment sleeves, etc., which are widely used in automobiles, electronics, etc.

Such products usually use natural rubber (NR), chloroprene rubber (CR), nitrile rubber (NBR), silicone rubber (SI), etc. Wear resistance, oil resistance, high temperature resistance and aging resistance need to be considered

A rubber dust cover is designed to shield components, machinery, and equipment from dust, debris, moisture, and other environmental factors that could impact performance and longevity. These covers are widely used in industries like automotive, electronics, industrial machinery, and healthcare to maintain equipment cleanliness and prevent foreign particles from interfering with functionality.

Rubber dust covers typically feature a snug fit over components to provide optimal protection. Flexibility, resilience, and compatibility with surrounding parts are crucial for the cover’s design.

EPDM (Ethylene Propylene Diene Monomer) gaskets are versatile sealing solutions known for their excellent resistance to weathering, ozone, UV radiation, and a range of chemicals. These gaskets are widely used across various industries, including automotive, HVAC, plumbing, electrical, and construction, where durability and resistance to environmental factors are essential.

Weather Resistance: EPDM gaskets are highly resistant to outdoor elements, making them suitable for applications exposed to UV rays, ozone, and extreme temperatures (typically from -40°C to 120°C).

Chemical Resistance: They are effective against a wide range of chemicals, including alkalis, acids, and some polar solvents. However, they are not suitable for use with petroleum-based oils and fuels.